AC/DC Power

Criterias for the calculation of AC/DC rectifier for DC systems

The AC/DC rectifier is considered an essential part of the DC power system. Therefore, the correct calculation of its capacity and electrical sizing is of vital importance.

However, this process must adhere to a set of technical safety criteria to ensure that the service it provides conforms to the reliability and uninterruptibility guidelines required by the critical systems it serves.

An example of this is in the field of telecommunications, where continuous availability throughout the year is crucial. Let’s now look at the globally recognized design criteria.

Criteria to follow for sizing the AC/DC rectifier

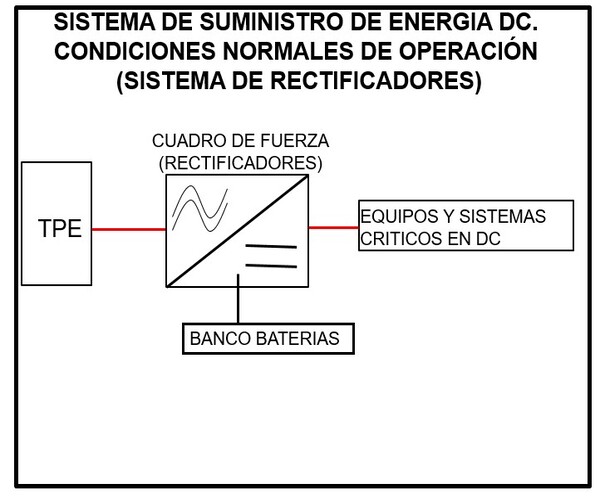

These devices are associated with a power cabinet that contains them, which is designed for a specific DC current capacity and voltage. However, it is the rectifiers that indicate its capacity at a given moment.

For example, if a power cabinet can provide 1000 Amperes but has 6 rectifiers of 100 Amperes each, then its available power is 600 Amperes.

The number of these rectifiers must be calculated considering the following parameters.

Current consumption and projected consumption in Amperes at the voltage of the equipment to be powered

Load (in Amperes) that they must provide during peak consumption or peak hours

Nominal capacity of the selected rectifiers. If it is an expansion, rectifiers with a nominal capacity equal to that of the existing rectifiers should be used

Voltage window of the equipment. The AC-DC rectifiers must be able to supply the maximum and minimum normal operating voltage of the loads

Consider growth in electrical equipment over a period of 5 to 10 years. If this information is not available, assume an increase between 15% and 25% of the current demand

Room temperature. AC/DC rectifiers must be able to operate at room temperature temporarily without damage. This ensures service continuity in case of air conditioning failures

Altitude above sea level. This is a variable that affects the performance of electronic components, especially in high-frequency technology rectifiers, as they are very sensitive to electrical and environmental variations

Redundancy criterion. Once you determine the number of required rectifiers, you should add 1 to this value. This ensures that the system is capable of maintaining service even with a faulty rectifier.

Do you want more information?

If you want to learn more about these devices, we invite you to read our article on Controlled and uncontrolled AC – DC rectifiers.

It is the beginning of an engaging series focused on them. Also, check out the post on Electrical power in telecommunication. These are the AC power source for rectifiers.

How do AC-DC rectifiers relate to batteries?

Batteries are the ones that keep the DC system running when the rectifiers fail for some reason and stop supplying power to the load. They also provide the necessary energy that, temporarily, the rectifiers may not be able to provide to cover the demand in its entirety.

For this purpose, they are connected to the system through the AC/DC rectifier, which must be capable of recharging the batteries within a maximum of 24 hours.

Now, you probably want to know how to size these components for an energy system. For that, we invite you to take our course on sizing and designing DC energy systems for telecommunications and critical systems.

In this course, we not only explain how to do it but also provide practical exercises on the subject. If you want to find out more about its content, just click here.

Additionally, we invite you to read our content on the energydcac blog, where you’ll learn everything about DC energy. Visit us and see for yourself!