AC/DC Power

Criteria for calculating generator set equipment

The proper selection of generator set equipment is as important as the selection of the generators themselves. Without them, the generator set will not operate or will do so inefficiently.

We are referring to the main fuel tank and the daily fuel tank. Also, the coolant compensation tank, oil compensation tank, and the automatic transfer switchboard (ATS).

This article is a continuation of Guidelines for calculating backup AC generator sets for DC systems. Although we will use the term ‘fuel,’ nowadays, most generator sets operate using ‘diesel’ as fuel.

Next, we explain the criteria for sizing each of them, following international standards. Let’s get started!

Main Fuel Tank (MFT)

The main fuel tank is the one that defines the autonomy time that the generator set will offer. Its sizing is done taking into account the following:

Installation class and its locatio

Which includes access roads, whether it is urban or rural, size and quantity of equipment, among others. Forthis, thefollowingmust be considered:

- For urban installations, the main fuel tank must have sufficient capacity to provide a minimum autonomy of 72 hours at full load

- Rural areas, In this type of installation, the load is relatively small, especially in areas that are not served.

Taking this into account, the main fuel tank must have sufficient capacity for the power plant to operate for 15 consecutive days at 100% of its load

Type of operation of the generator set

This refers to the operating regime of the generator set, which is specified below:

- Continuous operation, when it is estimated that the equipment operates 2 or more hours daily

- Stand-by operation, if the equipment is projected to operate only during power outages in the electrical grid. This implies an average of 2 hours or less daily for 20 days

As you can imagine, fuel consumption is higher for continuous operation. Therefore, the main fuel tank must have the appropriate volume.

Generator set capacity

When we refer to the capacity of the power plant, it is because the fuel consumption is directly related to the percentage of the connected load. This depends on the capacity of the generator set.

Since a higher percentage of load results in the engine consuming more fuel. And, obviously, with a larger capacity of the generator set, its fuel requirement is greater.

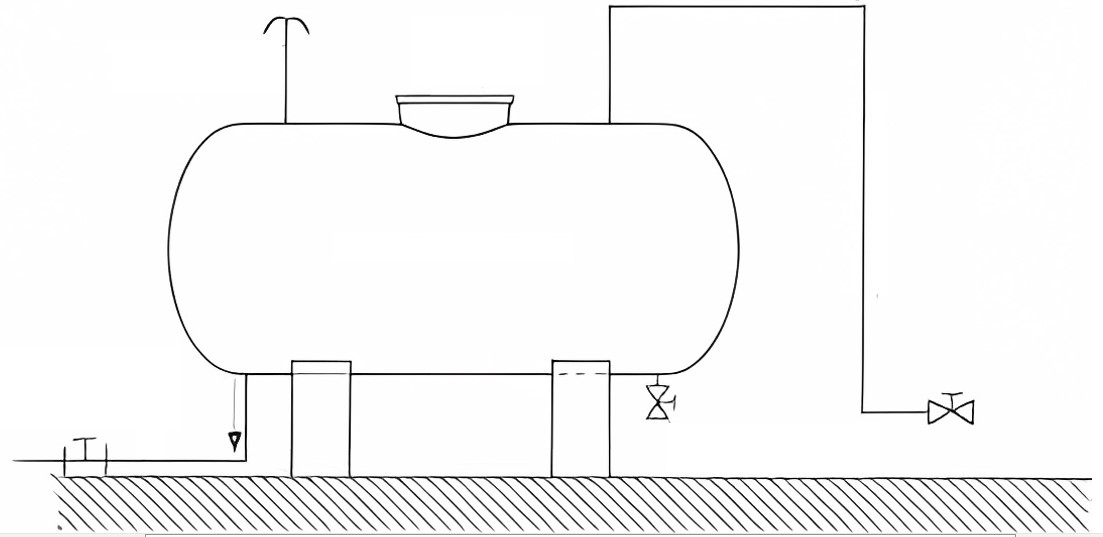

The daily fuel tank (DFT)

The daily fuel tank is placed between the power plant and the main fuel tank. It aims to prevent the engine from being directly fed from the main fuel tank with the fluid pressures that this implies. This tank adds to the available fuel capacity, both in terms of fuel and time.

In this latter sense, it must be sized in such a way that it can keep the generator running for 8 continuous hours at full load. Currently, most power plants come with the daily fuel tank built-in, calling it the «sub-base fuel tank”.

The oil compensation tank (OCT)

The function of the oil compensation tank is to replenish any oil that may be missing from the engine. Due to factors such as evaporation, temporary small leaks, and friction. Its minimum capacity is equivalent to 1.5 times the capacity of the engine’s crankcase.

The coolant compensation tank (CCT)

Compensates for the coolant that may be lacking in the engine cooling system due to various reasons. The minimum capacity of the coolant compensation tank should be 15% of the total volume required by the system.

Automatic transfer switch board (ATS)

This equipment is the one that detects the state of electricity and controls, automatically, the generator set. This includes its startup and shutdown, alarms, adjustments, among other functions.

Additionally, it is responsible for connecting the load either to the commercial power grid or to the generator set, depending on the conditions of these systems.

In the article What you need to know about automatic transfer switches in generator sets you will learn about its details. Don’t miss out on reading it!

The characteristics of the automatic transfer switch are based on the electrical dimensions of the generator in the generator set and the nominal voltage level.

In general, regarding its capacity, it should be 1,25 times the nominal current that the generator can supply.

On our website energydcac, you will find other articles related to AC and DC energy topics, so we invite you to read them. If you have any questions, we are here to help. See you soon!